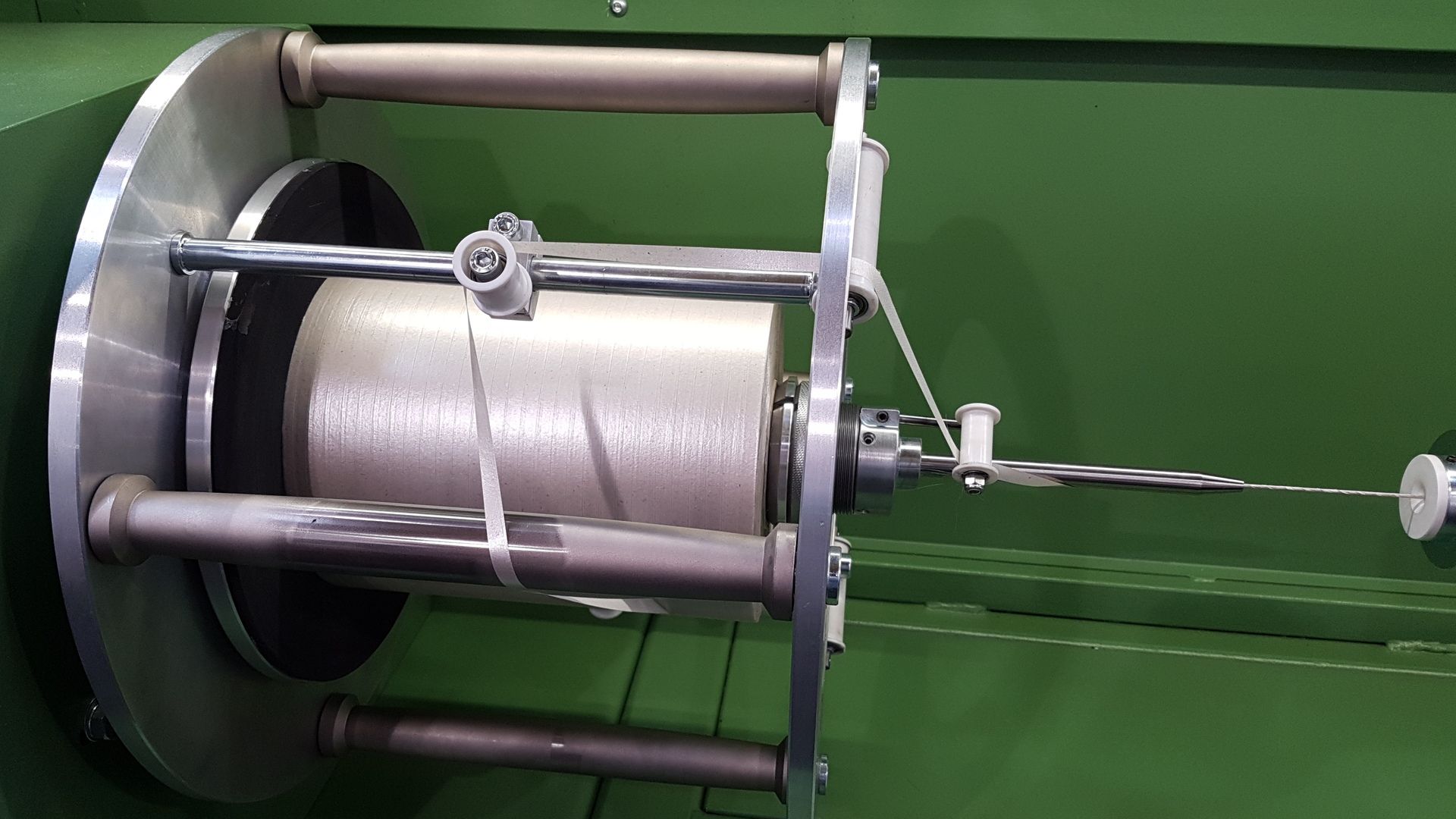

Horizontal taping machine

Horizontal taping line with high speed for spools and pads

High speed taping machine is made to reach the highest performance with different kind of materials, such as Mica-glass, Mica-polyester, Poliyammide, PTFE, Polyester and many others.

The electronic control system for the taping speed and the tension on the tape elaborates all the main elements of the material used, such as the specific weight and the dimension of the spool or pad and dynamic friction.

With this system we have always the right tension on the tape during the running of the machine, also when we are increasing or decreasing the speed.

On the HMI it is possible to set the tension on the tape from 1 up to 25N.

The high speed taping machine is made in vertical or horizontal lay-out according the request of the customer and the space available.

The taping line can be complete with take-up and pay-off with motor and mechanical dancer with loading cell to have a very precise control on the wire tension otherwise with manual, pneumatic or electronic brake. Dimensions of the take-up and pay-off according the customer request.

The PLC communication with the motors drives and the HMI is with the high speed protocol Profinet.

All the motors are brushless type with very high performance and maintenance free. With this motors we have an accurate control of the speed and tension on the tape.

From the HMI it is possible to set the barrel diameter of the pad or the spool: the machine will stop before ending the tape or in case of breakage.

The measure of the meters produced is made with an encoder with a very high number of pulse to obtain an accurate counting.

In the HMI it is possible to save the most produced cable parameters.